SHIBATA- FENDERTEAM RELEASES THE 3RD WHITE PAPER EDITION , WHICH FOCUSES ON MANUFACTURING AND CURING PROCESS

Months of hard work lie behind us. Finally, we announce:

ShibataFenderTeam Group releases the third White Paper which focuses on manufacturing and curing processes.

As you know, our four-part White Paper Series aims to provide an unbiased view of “what exactly makes a good fender”.

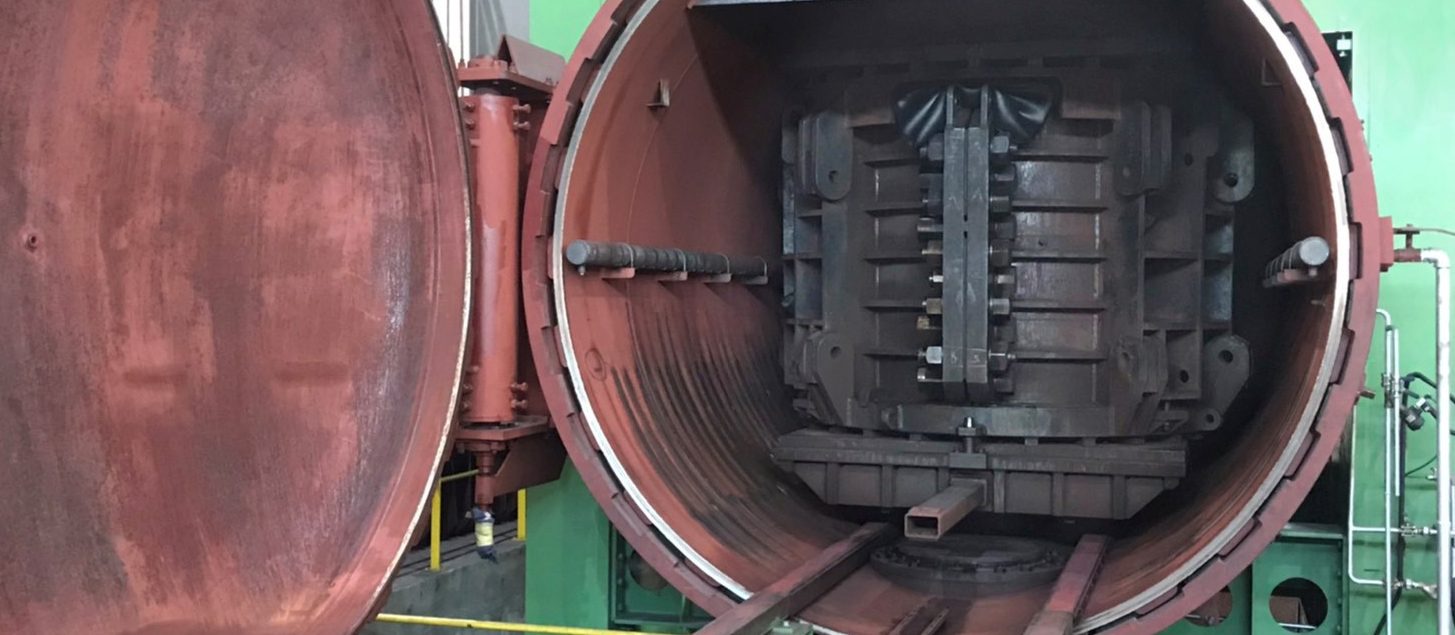

Paper #3 takes a close look at manufacturing and curing as two of the most quality-critical steps in the fender industry. It outlines the optimal methods for each fender type and size and how the most important parameters temperature, pressure, and time play a decisive role in the advanced stage of fender production.

- Get to know different manufacturing and curing methods

- Learn why the correct pressure, temperature, and time is so important for a high-quality fender

- Understand why more transparency in fender production is important for the industry

The release of the third White Paper is a very important step for the company. We can once again demonstrate our know-how and expertise to the industry and clearly encounter common misleading statements.

As a leading fender manufacturer it is our task

- to educate the industry to be aware of the quality-determining parameters

- to make clear once more to which extent high-quality fender production depends on the expertise of the manufacturer

Enjoy reading!

Please forward the White Paper to relevant contacts or forward the link: https://www.shibata-fender.team/en/white-paper-part-iii-manufacturing-and-curing.html

Paper #3 is available as a free download.